Tradition and innovation

The story

our company

Swiss Quality Paper AG has been manufacturing high-quality paper products since it was founded. The paper mill looks back on a long and eventful history.

In all these years, she has successfully navigated through an environment that is constantly undergoing major changes. Several times she has stood out as a pioneer and become known worldwide with innovations and specializations.

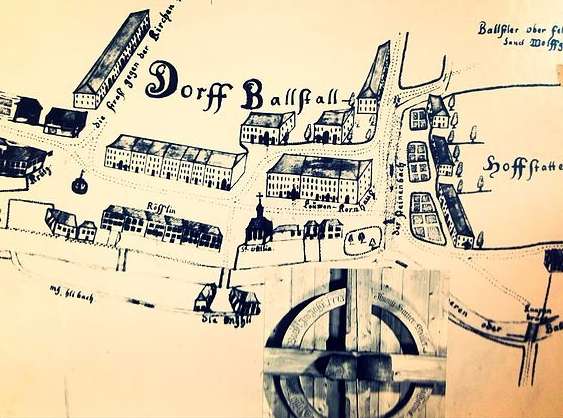

Industrial paper production in Balsthal begins in 1883. Robert and Arthur Bareiss found the limited partnership Papier- und Couvertfabrik Balsthal and install the first paper machine one year later. But the roots of the company go back even further: to a medieval grain mill and a wood grinding mill.

A second paper machine with a smoothing cylinder is put into operation. With this, one-sided smooth papers for toilet paper books and rolls as well as envelopes can be made - a pioneering achievement. Until then, such products had to be imported from abroad. In a short time, the factory produces a wide variety of products, including exercise book covers and candy cane paper.

From 1900, paper processing is further expanded so that office papers can also be produced. In 1911, the entire plant is electrified. Two more paper machines are installed. This means that printing and writing paper, cardboard, tissue paper and thin parchment can also be produced.

The Coba envelope factory is established. Paper processing is further expanded.

Paper machine 5 with smoothing cylinder for tissue paper is introduced.

In 1929, a new speciality, cellular cotton wool for hygienic purposes, is introduced. In 1933, the trademark "Tela" is registered for cotton wool products. At the beginning of the Second World War, the 6th paper machine is put into operation, which is used almost exclusively for the production of cellular and dressing wadding.

The Coba envelope factory is sold.

Paper processing is further expanded for finished products. In 1957, a paper machine is converted into the first tissue machine in Europe.

Construction of a second mill in Niederbipp. In 1966, base papers from Balsthal can be processed at the new site for the first time. In addition, Switzerland's first industrial wastewater treatment plant is put into operation. Three years later, Tissue Machine 1 comes on stream, producing the finest crepe tissue paper with advanced technology, high speed and precision. For the first time in the world, the paper machine water circuit is completely closed. As a result, fresh water consumption can be reduced to a previously unimaginable minimum.

The computer is introduced in the administration.

The company that owns Tela Papierfabrik, Attisholz-Holding, takes over 75 percent of the shares in Hakle AG in Mainz. A new workshop building is constructed in Niederbipp.

The Attisholz Group is transformed into a holding company comprising Hakle Mainz, Hakle Reichenburg, Tela Papierfabrik AG Balsthal and Niederbipp, Attisholz and Vlesia.

Pressed recycled stock (wet-lab) is used for the first time on paper machine three in Balsthal.

A devastating fire destroys the entire processing plant in Niederbipp. Production is restarted in the Klus in Balsthal.

The entire hygiene division of Attisholz Holding is sold to Kimberly-Clark, an American manufacturer of sanitary paper. Tela AG is renamed Tela-Kimberly (Switzerland) GmbH.

Kimberly-Clark closes the Hakle plant in Reichenburg and sells the plant in Balsthal to Papierfabrik Horgen Holding AG. The company is renamed Swiss Quality Paper Horgen Balsthal AG.

The Soin family from India takes over the company and it is renamed Saber Swiss Quality Paper AG. The production strategy revolves around the manufacture of specialty papers for masking tape paper, cigarette filter paper and hygiene products.

Swiss Quality Paper AG is detached from the Saber Group and focuses again more on the Swiss identity of the mill and its qualities.

Rebuild of the stock preparation system. The implementation of a large-scale project makes separate grinding possible, and at the same time a new process control system is installed and put into operation, and a transformer system is installed.

A steam turbine for energy production is put into operation and produces since then about 200'000kWh to be ready for future projects and installations.

In 2020, the focus is on the health of the company's own employees. The awareness of one's own vulnerability led to a sensitization of sustainability thoughts in the management. This changes the strategies and investments in the future. The challenges of the year have led to planning difficulties and resource shortages. Thanks to its structured working methods and well-connected employees, Swiss Quality Paper AG has always delivered on time, which has made us favoured suppliers to large customers.

Various product developments are planned and investments are being examined in order to meet the increased demand.